Masterbatch nero antiumidità 2 5% Dosaggio per un consumo ridotto di Masterbatch nero

Descrizione del prodotto:

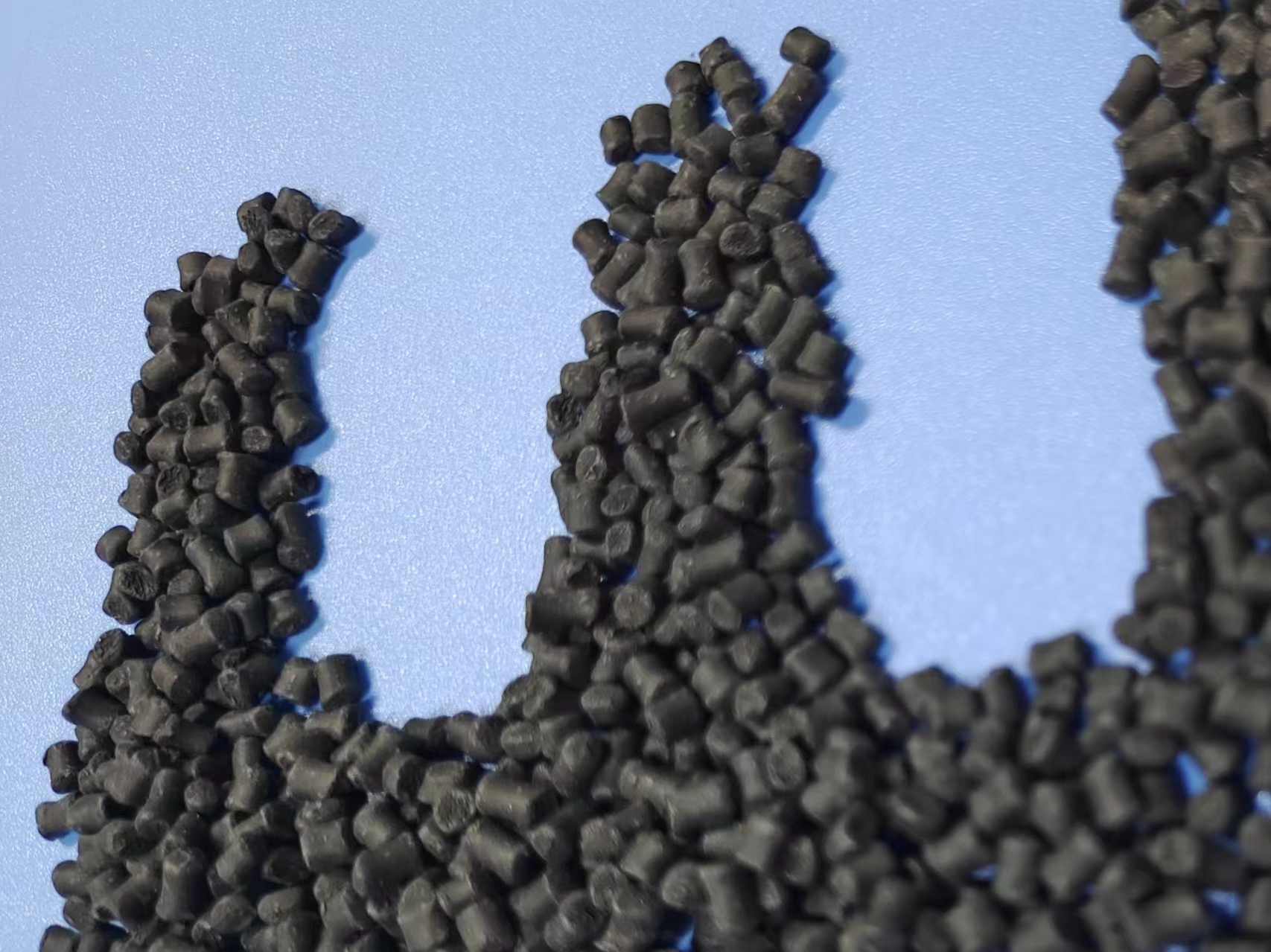

Questo Masterbatch per la defoaming è un additivo specializzato progettato principalmente per prodotti di plastica stampati a soffio.e ottimizza l'efficienza della produzioneIl prodotto è fornito sotto forma di granuli neri.

Essendo un agente di defoaming ad alte prestazioni, riduce significativamente le bolle interne negli articoli in plastica e migliora l'aspetto complessivo del prodotto.È ampiamente utilizzato in tutti i processi di stampaggio a soffio per i suoi risultati coerenti e vantaggi di risparmio di costi.

Caratteristiche chiave:

- Nome del prodotto: Masterbatch di defoaming

- Dosaggio raccomandato: 2-5%

- Funzioni principali: eliminazione dell'umidità, riduzione dell'uso di masterbatch nero

- Vantaggi principali: eccellente effetto di colorazione nera

- Composizione: comprende agenti antifoame, masterbatch antiumidità e componenti essiccanti

Le specifiche tecniche:

| Parametro |

Valore |

| Nome del prodotto |

Masterbatch per la deformazione della schiuma |

| Contenuto di cenere |

≤ 0,3% |

| Modulo |

Granuli neri |

| Resistenza alla trazione |

≥ 3Mpa |

| Resistenza al calore |

≥ 80°C |

| Allungamento alla rottura |

≥ 200% |

| Punto di fusione |

110-130°C |

| Densità |

10,2-1,4 g/cm3 |

| MFI (190°C/2,16kg) |

2-20 g/10 min |

| Materia volatile |

≤ 0,3% |

| Parole chiave |

Masterbatch antiumidità, Masterbatch essiccante, assorbente di umidità, agente essiccante |

Applicazioni:

Il Masterbatch di defoaming di Ecoplas Material® funge da additivo antifoame e essiccante altamente efficiente, riducendo efficacemente la formazione di bolle e migliorando la qualità superficiale dei prodotti in plastica.Composto da granuli neri di qualità superiore, ha un punto di fusione di 110-130°C e una densità di 1,2-1,4 g/cm3, nonché una resistenza alla trazione ≥ 3 MPa.

Questo masterbatch è ampiamente utilizzato in vari settori di lavorazione della plastica, tra cui lo stampaggio a iniezione, lo stampaggio a soffio, l'estrusione e la calandratura.È una soluzione ottimale per la produzione di prodotti in plastica di alta qualità ed elimina i difetti legati alle bolle d'aria e all'umiditàL'integrazione di questo masterbatch consente ai produttori di ridurre i costi di produzione e di migliorare la consistenza del prodotto finale.

Affidato da numerosi produttori di plastica per la sua affidabilità e prestazioni superiori, il Masterbatch di defoaming di Ecoplas Material® soddisfa i più elevati standard di sicurezza e qualità.Se l'obiettivo è quello di raggiungere condizioni di lavorazione stabili, riducendo il consumo di colorante nero, o garantendo l'eccellenza del prodotto, questo masterbatch offre una soluzione ideale.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!